The benefits of PVC foam board, an easy and innovative marketing solution that keeps everything safe

Do you need more robust materials to add a fire under your marketing strategies? Well, is that PVC foam boards! Extrusion is a manufacturing process in which raw materials are melted and take solid shape. This also explains why PVC foam boards are high-quality products and have numerous advantages. In this guide we are going to talk about the production, Advantages and disadvantages innovation safety need of PVC foam boards or sheets.

Learning About Production

PVC foam boards are developed carefully from a combination of polyvinyl chloride (PVC) and numerous materials. They are typically shaped through an extrusion process where the materials melt at high temperatures. This molten mixture is later passed through a die to get the final shape. Different Plies & Ratios in final products to suit different requirements

Revealing the Benefits of PVC Foam Boards

PVC foam board are popular choice of advertising materials due to its versatility. Aside from that, these boards are ultrasonic so lightweight and durable but also weatherproof. Long-lasting and durable - they even hold up over time when exposed to the harshest sun or moisture. PVC Foam Board is additionally easy to clean They can be cut, drilled and formed into many shapes.

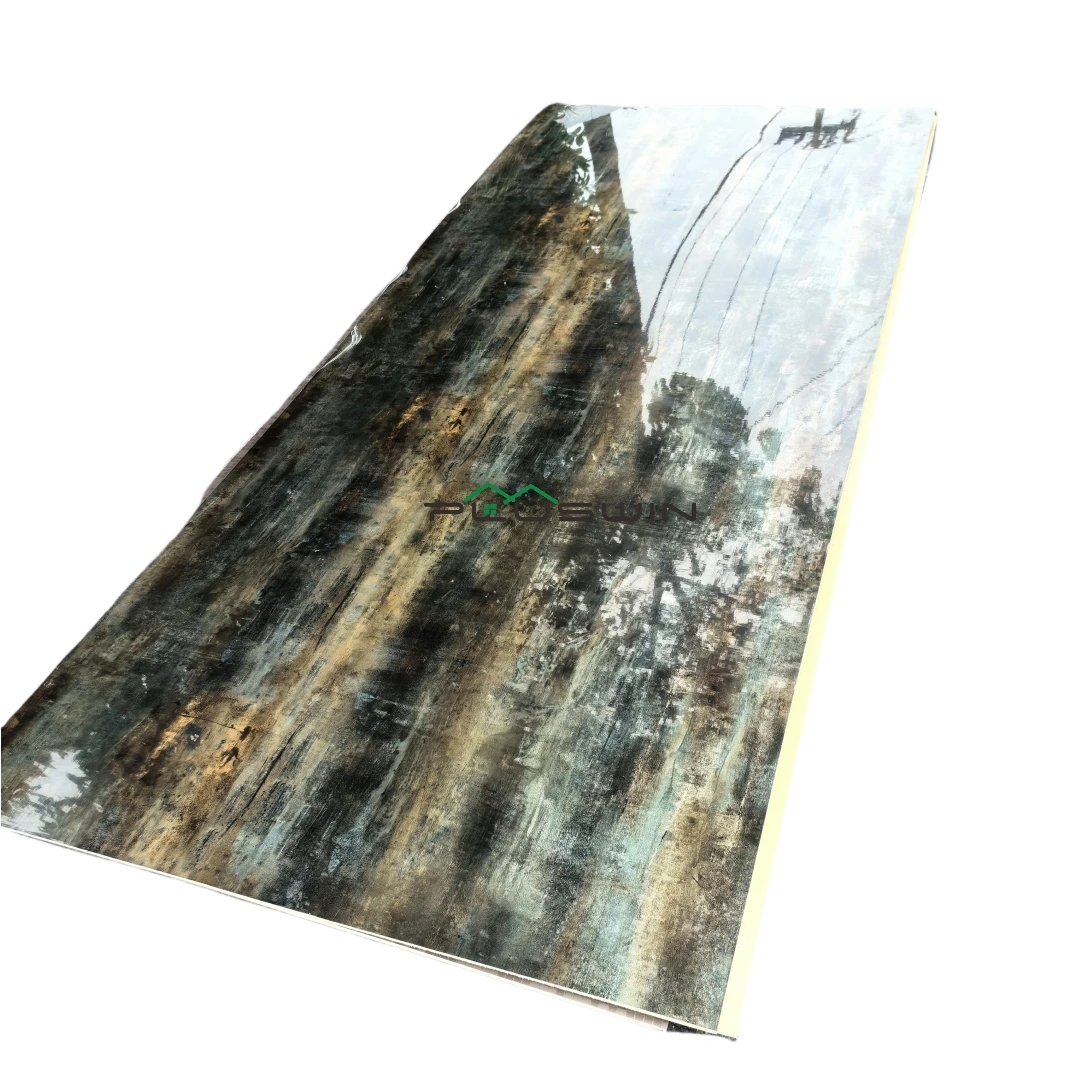

Advancements in PVC Foam Board Production

Modern PVC foam boards now represent significant advances in quality. Manufacturing state-of-the-art Manufacturing techniques result in board consistency from tip to tail. Furthermore, advancements in printing technology allowed PVC foam boards to be manufactured with the high-definition full-colour print on eco-solvent or latex Inks.

Guarding Using PVC Foam Boards

One major feature of PVC foam boards is that it offers safety, as well at being environment friendly. They are furniture boards with nothing that would be dangerous for health or the environment. In addition, PVC foam boards can be recycled and reused again even after being used for the first time.

PVC Foam Boards - The versatility of this Alternate to Wood!

PVC foam boards have a lot of marketing applications. Perfect for POS displays, retail signage, exhibition stands and trade show exhibits Besides, using PVC foam boards, customized branding and signage can be created for business events, offices as well other establishments.

Easy to Handle PVC Foam Board

PVC foam boards are easy to process. They are easy to cut with a sharp blade, saw or CNC router and can be cut down in size. Hand- or router-jigsaw For difficult forms PVC foam boards can be attached to surfaces using stickers, silicone adhesives, glue sticks and hook & loop fasteners.

Quality Service at Jiaying

At Jiaying, we take great pride in providing the finest PVC foam boards and personalized customer service. We offer our boards in various thicknesses, colors and lengths. In addition, our cutting and printing services guarantee the fine-tuned quality of your PVC foam boards. You can rest easy knowing that we offer the best quality PVC foam boards out there and come with our exceeding record of customer satisfaction.

Uses of PVC Foam Board

The application of these PVC foam boards are innumerous. These include retail environments, event displays and corporate branding (as well as a sign), construction projects where soundproofing or insulation is required used in walls and ceilings.