Ak chcete detegovať produkty z PVC penu, potom budete potrebovať niekoľko nevyhnutných nástrojov. Sú to ukazovatele bezpečnosti a kvality/hodnoty, ktoré môžete použiť na vyhodnotenie dosiek, ktoré máte k dispozícii. Pravítko __ Krok 1: Prvý nástroj, ktorý potrebujete. Pravítko je nevyhnutné na presné mierenie rozmierov dosky. To je dôležité, pretože chcete testovať s správnymi rozmiermi. Ďalej budete potrebovať váhu. Váha pomáha ovládnuť hmotnosť dosky, čo vám pomôže pochopiť, ako je leká alebo ťažká vaša doska. Okrem pravítka a váhy budete tiež potrebovať pH meter. pH meter je špeciálny merací nástroj, ktorý meria kyslosť dosky. Kyslosť by mohla ovplyvniť výkon vašej dosky, preto je to hodnota, ktorú stojí za to zohľadniť. Posledným príslušenstvom, ktoré potrebujete, je mikroskop. Je to zariadenie, ktoré zväčší porov dosky tak, aby boli viditeľné, takže ich môžete pozorovať detailne a uvidieť problémy pod alebo vnútri materiálu. Toto je dôležitý spôsob, ako nájsť defekty, ktoré nie sú viditeľné voľbou oku.

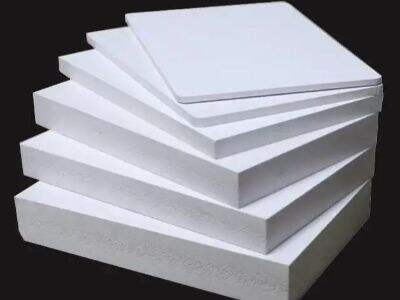

Testovací proces produktov z PVC penu

Jednoducho si môžete vyskúšať produkty z PVC penu po tom, ako máte všetky nástroje pri ruke. Prvým krokom je zmieranie a váhovanie svojej dosky. Najprv změrte dĺžku a šírku dosky pravítkom. Keď už budete mať tieto merania, položte dosku na vahu, aby ste zistili jej hmotnosť. Táto informácia je kľúčová pre ďalšie kroky. Skontrolujte pH úroveň (zmierajte a vážte dosku). Vezmite pH metier a změrte, ako kyselá je vaša doska. Tieto kroky sú nevyhnutné pre bezpečnosť a výkon vašej dosky. Po kontrole pH môžeme použiť naše mikroskopium. Pečlivo pozorujte malé diery na vrchnej časti dosky a jej vnútornú štruktúru. Tak urobíte tak, aby ste mohli identifikovať akékoľvek trhliny alebo defekty, ktoré môžu ovplyvniť kvalitu dosky. Nakoniec sa uskutočnia niektoré testy na pevnosť. Tieto testy by mali odpovedať na otázku, ako tvrdá a odolná je doska. Dôležité je skontrolovať kalibr, aby bola schopná vydržať rôzne podmienky.

Bežné testy produktu z PVC penu

Nižšie sú uvedené niekoľko testov, ktoré by sa mali vykonať na produktoch z PVC penu. Tieto testy vám ukážu všetko o jej výkone *** - keď sa týkajú, samozrejme; inak som mlčal. Prvým krokom pri testovaní dosky je skontrolovať jej hustotu. Hustota je to, ako ťažká je hmotnosť dosky vzhľadom k jej objemu. Prečo je to dôležité - môže to mať vplyv na kvalitu dosky. Druhou najdôležitejšou vecou je absorpcia vody vo vašej doske. Takto si môžete overiť, koľko vody doska absorbuje po opakovanom kontakte. Je dôležité otestovať, koľko vody vstresuje, pretože to môže ovplyvniť jej pevnosť a trvanlivosť. Krok 3: Test prúdenia na izoláciu dosky V tomto prípade sa testuje, ako dobre poskytuje doska teplo alebo chlad. Veľa aplikácií vyžaduje dobrú izoláciu. Ďalej sa pozrite na toxickosť dosky. Ide o to vedieť, ako toxická je pre ľudské bytosti, ako aj pre prirodzené prostredie. Bezpečnosť vždy! Nakoniec musíte vykonať test na ohnúvanie. Test na ohnúvanie ukazuje, ako peknú a silnú je doska. To je prospešné, pretože flexibilita môže byť často potrebná podľa toho, ako bude doska nakoniec používaná.

Príručka k výsledkom testovania PVC penuchých dosiek

Keď už ste dokončili všetky testy, je čas tieto výsledky pochopiť. Dnes, aby sme overili kvalitu PVC penuchých dosiek, potrebujeme niekoľko základných kvalít: Prvoučinou je mať vysokú hustotu. Druhou je byť málo prónikavou pre vodu, pretože to môže dosku rozložiť. V chaotickom prostredí štátu Washington určite pomáha, že tento materiál môže držať teplo von alebo vnútri a je tiež vhodný na izoláciu. Predtým musí byť stabilná a byť neštvrdoxicná pre dosku. Nakoniec, doska musí byť aj flexibilná a trvanlivá. Ak výsledky nie sú také, aké by mali byť, musíme nájsť, kde sa niečo pokazilo. Zamyslite sa nad tým, čo môžete zmeniť, aby doska lepšie fungovala. Výsledky môžu byť objektívne, no získať pochopenie povrchu a navyše, ktoré sú dostupné PVC penuché listy, aby ste ich porovnali s vaším.

Udržiavanie kvality a bezpečnosti pri diagnostike PVC penuchých dosiek

Dôsledkom dodržiavania niektorých základných pravidiel zabezpečíte, že vaše testy budú bezpečné a kvalitné. Najprv, nástroje a materiály na vysokokvalitné testovanie. Nájdenie správnych nástrojov je rovnako dôležité pre odhalenie relevantných údajov. Pečlivne dodržiavajte pokyny a takto získate výsledky testov vhodné pre vás. Nasledujte bezpečnostné pravidlá. Toto zahŕňa používanie ochranného oblečenia ako sú rukavice a brýle, okrem toho pracujte v dobre ventilovanom priestore. Bezpečné testovanie - stále je to superdôležité. 3- Držte produkty z PVC pénovej dosky čisté a hygiénne: Čistý pracovný priestor zabráni kontaminácii vášho práce. Nakoniec je dôležité, aby nezávislá organizácia mimo vašu spoločnosť overila váš produkt. Táto certifikácia zabezpečí kvalitu vašich produktov.

Nakoniec je testovanie produktov z PVC penu dôležité na to, uvidieť, či sú hodnotné a či sú chránené alebo nie. Takže dodržiavaním krokov a pravidiel, ktoré uvádzame, môžete vykonať lepšie kompletné testy. Identifikovaním problémov môžete podniknúť opravné opatrenia pre lepšie produkty v budúcnosti. Kvalita a bezpečnosť musia byť na prvom mieste v vašom testovacom procese, čo vás prinúti vytvoriť skvelý a užitočný produkt pre vašich zákazníkov. Najlepšie testovacie postupy = lepšie produkty.