Хотя твердый ПВХ, безусловно, более прочный, чем пенополивинилхлорид, это не означает, что он является правильным выбором для вашей задачи. Например, твердая версия предлагает высокоглянцевое покрытие, часто используемое в облицовке стен, но его пенный аналог также подходит для того же применения благодаря другим преимуществам.

Что такое материал ПВХ?

Для производства пеноматериалов и твёрдых листов ПВХ сначала требуется общий состав ПВХ. Поливинилхлорид, или ПВХ, является термопластичным полимером, получаемым из множества мономеров, что делает его синтетическим пластиком.

Из-за большого количества компонентов его часто сложно перерабатывать, и он считается одним из самых вредных пластиков для окружающей среды. Однако ПВХ также является повторно используемым материалом, так как его можно измельчить в порошок, превратить в гранулы и затем снова сформовать в новые продукты. Зная это, его также можно считать одним из самых универсальных материалов.

Существует несколько типов ПВХ, таких как уПВХ, пПВХ, CPVC и ПВХ-О. Каждый из них имеет свои применения и преимущества, будь то прочный оконный профиль или гибкий электрический кабель. Но что такое пенный ПВХ и его твёрдый аналог?

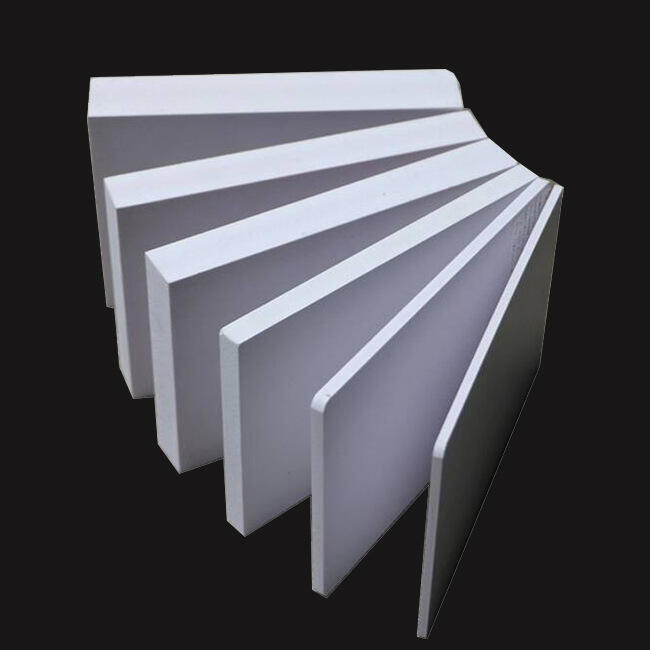

Что такое пенный ПВХ?

Пенополивинилхлорид (Foam PVC) — это легкий материал с мягким и слегка неровным текстурным рисунком,主要用于 теплоизоляции. В отличие от своего несколько вводящего в заблуждение названия, он не похож на обычные пористые материалы, поэтому не будет легко гнуться или ломаться при надавливании.

Пенополивинилхлорид (Foam PVC) — это легкий материал с мягким и слегка неровным текстурным рисунком,主要用于 теплоизоляции. В отличие от своего несколько вводящего в заблуждение названия, он не похож на обычные пористые материалы, поэтому не будет легко гнуться или ломаться при надавливании.

Смесь обычного ПВХ и полиуреи придает пенополивинилхлориду прочное соединение и устойчивую форму. Поскольку он имеет закрытоячеистую структуру, его можно легко резать, забивать гвоздями и крепить саморезами, а также он может становиться мягким (и даже менять форму), если оставить его в кипящей воде.

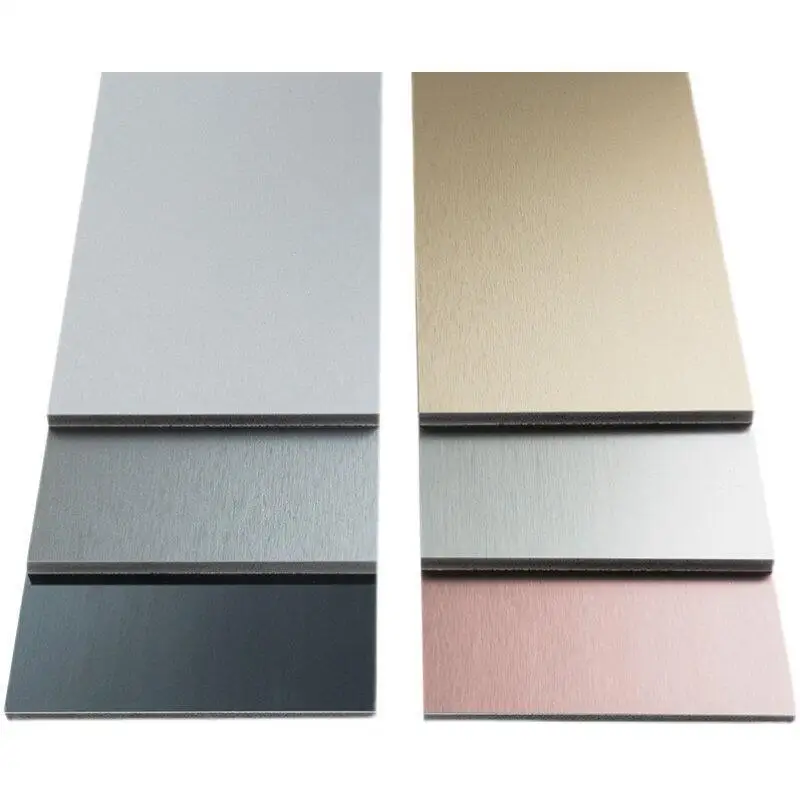

Что такое твердый ПВХ?

Твердый ПВХ немного тяжелее, чем его пенная альтернатива, что делает его еще более долговечным. Однако пенный и твердый ПВХ были созданы для совершенно разных целей. На самом деле, акриловые и поликарбонатные листы больше похожи на твердый ПВХ, учитывая его области применения и преимущества.

Его гладкая текстура и твердая форма позволяют придать ему различные формы для разных применений, а также легко резать с помощью стандартных электроинструментов. В отличие от пены ПВХ, этот материал можно изгибать, чтобы скрыть непривлекательные конструкции, такие как провода и трубы, или использовать в качестве укрепления, например, подставки или экрана.

Применение пеноматериала ПВХ vs твердого ПВХ

Пеноматериал ПВХ и его твердый аналог имеют сильно контрастные свойства и области применения. Перед выбором материала важно понять все требования вашего проекта.

Например, пеноматериал ПВХ часто используется в морской и пищевой промышленности, но не все виды пены подходят для этих применений. В сравнении, твердый ПВХ может быть подходящим для изголовья кровати, но та же толщина не подойдет для спинки кровати.

Как только у вас есть спецификации, вы можете выбрать толщину, размер и тип ПВХ, который вам действительно нужен для вашего проекта. Как общее руководство, ниже указано, для чего подходят пена и твердый ПВХ:

Применение пеноматериала ПВХ

- Художественное произведение

- Стаканы и контейнеры

- Прокладка

- Декорации

- Стельки

- Перегородки

- Печать

- Декорации

- Снаряжение для плавания

- Стекольные облицовки

Применение твердого ПВХ

- Билборды

- Дисплеи

- Электрические коробки

- Полосы для архивации

- Папки

- Зоны приготовления пищи

- Ширмы/кроватные щиты

- Указатели

- Подставки

Преимущества пеномассового и твердого ПВХ

При выборе между пеномассовым и твердым листами ПВХ мы рекомендуем изучить их преимущества перед принятием решения. Поскольку они подходят для широкого спектра применений, можно ожидать, что у них будет столько же преимуществ. Вы должны помнить, что существуют различные марки ПВХ, которые изменяют способность этих преимуществ.

Преимущества пеномассового ПВХ

- Защита от коррозии

- Не отслаивается

- Прочные

- Теплостойкость

- Упорность на удар

- Сохраняет форму на протяжении лет

- Легкий

- Долговечный

- Водостойкость

- Устойчивы к воздействию атмосферных условий

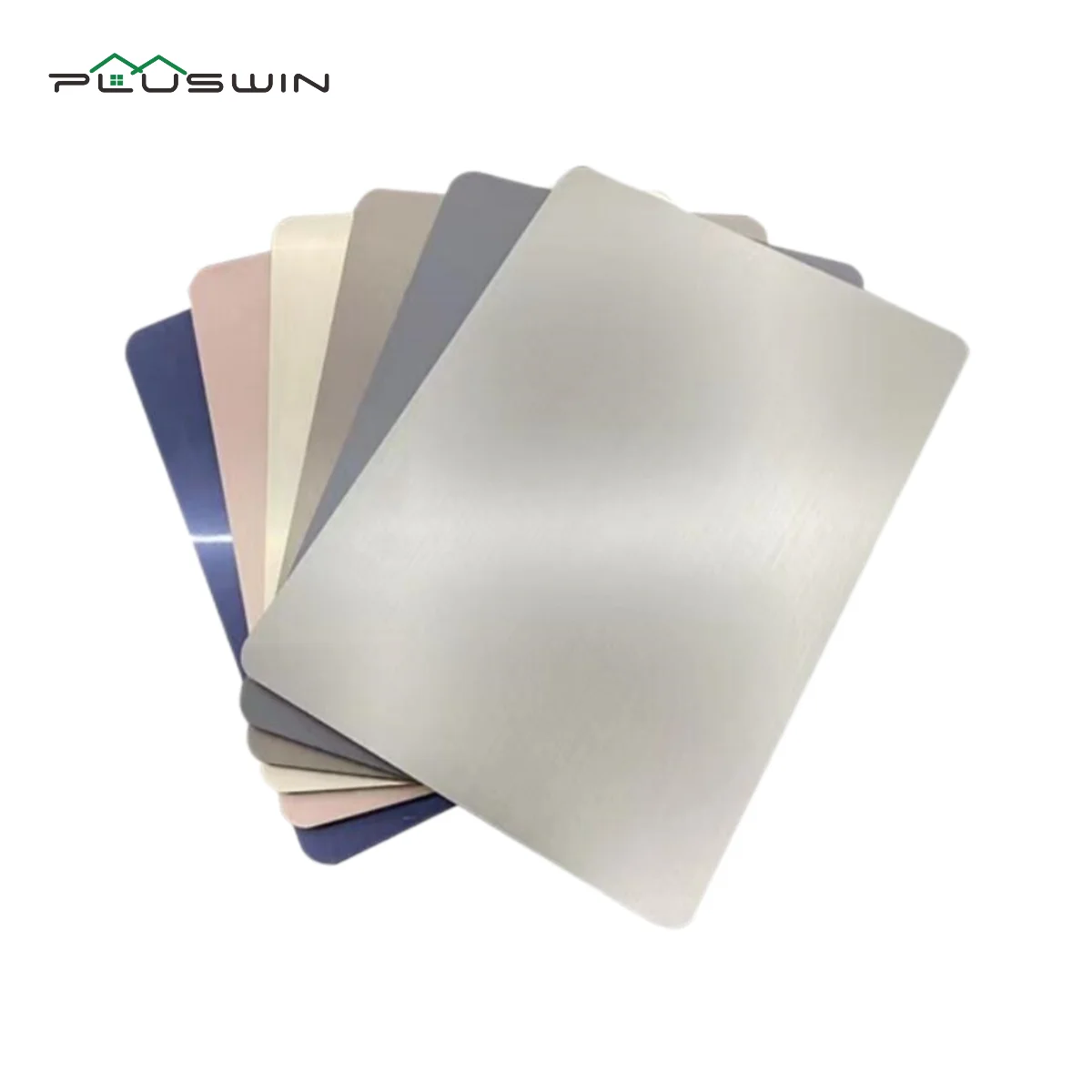

Преимущества твердого ПВХ

- Устойчивость к химическим веществам

- Четкая печать

- Легко изготовить

- Блестящая отделка

- Высокая устойчивость к ударам

- Устойчивость к влаге

- Непористый

- Гладкая и ровная поверхность

- Прочный и жесткий

- Хорошо работает с клеями

Что лучше? Пеноматериал ПВХ или твердый ПВХ?

В конечном итоге, выбор между пеноматериалом и твердым ПВХ полностью зависит от вас. Окончательно всё решают ваши требования, такие как назначение, размеры, толщина, преимущества и общий внешний вид. В Sheet Plastics мы можем проконсультировать вас по всем этим вопросам, чтобы обеспечить вас лучшим материалом и результатом.

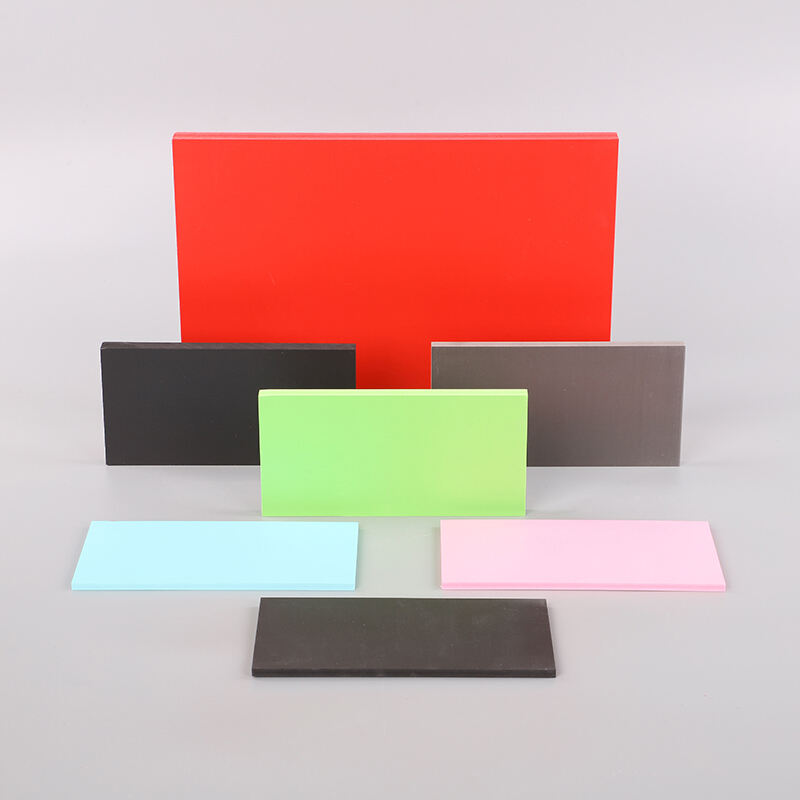

Листы пеноматериала ПВХ по индивидуальному размеру в Sheet Plastics

Мы предлагаем широкий ассортимент высококачественных пеном ПВХ подходит для многих применений. Будь то ярко-желтая стеновая облицовка, чтобы привлечь новых клиентов, или элегантный матовый белый лист для вывесок, у нас есть подходящий продукт для вас.

Мы предлагаем широкий ассортимент высококачественных пеном ПВХ подходит для многих применений. Будь то ярко-желтая стеновая облицовка, чтобы привлечь новых клиентов, или элегантный матовый белый лист для вывесок, у нас есть подходящий продукт для вас.

СВЯЖИТЕСЬ С НАМИ сегодня с любыми вопросами о наших листах пеном ПВХ или для начала вашего проекта. Кроме того, протестируйте материалы самостоятельно перед принятием решения, заказав образец образец .